Pallet Stacking

Languages: English

Media Editing: The video module(s) in this subject are editable under our Content Studio offering unless otherwise indicated. For more information about Content Studio, contact your CSM.

Description: Stacking pallets is a necessary task for transporting inventory, but it can also be a dangerous one if done improperly. It’s important that employees have the knowledge and skills to properly stack and store pallets to maintain their own safety and avoid damaging the pallets or the items on them. In this subject, employees will learn how to safely handle and move pallets, how to store idle pallets, how to load and secure items onto pallets, and different pallet stacking methods they should use based on what items are being loaded.

Languages: English

Media Editing: The video module(s) in this subject are editable under our Content Studio offering unless otherwise indicated. For more information about Content Studio, contact your CSM.

Description: Stacking pallets is a necessary task for transporting inventory, but it can also be a dangerous one if done improperly. It’s important that employees have the knowledge and skills to properly stack and store pallets to maintain their own safety and avoid damaging the pallets or the items on them. In this subject, employees will learn how to safely handle and move pallets, how to store idle pallets, how to load and secure items onto pallets, and different pallet stacking methods they should use based on what items are being loaded.

Languages: English

Media Editing: The video module(s) in this subject are editable under our Content Studio offering unless otherwise indicated. For more information about Content Studio, contact your CSM.

Description: Stacking pallets is a necessary task for transporting inventory, but it can also be a dangerous one if done improperly. It’s important that employees have the knowledge and skills to properly stack and store pallets to maintain their own safety and avoid damaging the pallets or the items on them. In this subject, employees will learn how to safely handle and move pallets, how to store idle pallets, how to load and secure items onto pallets, and different pallet stacking methods they should use based on what items are being loaded.

Topics

How to Safely Handle Pallets

-

There are various safety measures you must take before handling pallets at work, whether they’re empty or already loaded. This subject will teach you what to do before handling a pallet, what to avoid doing when handling a pallet, and how to help make sure everyone else around you is safe while you handle the pallet.

-

Questions (level 1, 2, 3)

Video module

-

This topic is currently available in English.

-

Wear personal protective equipment (PPE), like gloves, industrial boots, and a head shield, to protect your body whenever you’re handling pallets and their materials.

Inspect pallets before you use them and look for any damage to the pallet, like chipped or bent wood. If a pallet is damaged, avoid using it and remove it from service so it can be replaced.

Avoid over-stacking pallets that could compromise the strength of the bottom pallet. If you stack too much weight on the bottom pallet, it could break and damage the loaded items.

Clear the areas around the pallet so it can safely be stacked and transported without any barriers, and make sure pallets aren’t blocking emergency exits.

Avoid stacking or placing pallets in front of electrical outlets, sprinklers, ventilation ducts, or light switches that might need to be accessed since the pallet could block them and is too heavy to simply move out of the way.

Do not stand or climb on pallets regardless of whether they’re empty or have items stacked on them because it can be a safety hazard and cause damage to the pallet.

Check the weight limit of the forklift, pallet jack, or equipment being used to move pallets before loading them onto the equipment.

How to Store Idle Pallets

-

Pallets are large, heavy, and can get in the way if they’re not stored correctly. This subject will teach you where to store idle pallets within your workplace, how they should be stacked so they don’t cause a hazard, and the machinery you should use to move idle pallets.

-

Questions (level 1, 2, 3)

Video module

-

This topic is currently available in English.

-

An idle pallet is a pallet that is not currently being used, meaning it has no materials on it and sits in one place.

If possible, store idle pallets outdoors or in a designated area that is away from hallways and hazardous materials indoors since they are flammable.

Stack idle pallets on a flat, even surface, and never stack them on their side because they could tip over and get damaged.

Use a forklift or pallet jack to move and stack idle pallets. Moving them manually, even if it’s just one pallet, increases your risk of injuring yourself or damaging the pallet.

Stack empty idle pallets to a maximum of 15 feet high but note that height restrictions on loaded pallets may vary based on the kind of product the pallet is holding.

Loading and Securing Pallets

-

When it’s time to load an empty pallet, it’s important that you know the best techniques to help you and the merchandise stay safe. This topic will teach you how to load and stack items onto a pallet, which types of items go where on the pallet, and how to secure the items on the pallet.

-

Questions (level 1, 2, 3)

Video module

-

This topic is currently available in English.

-

Load the heaviest products and boxes on the bottom of the stack to provide a strong base on the pallet and prevent the lighter packages from being damaged.

When loading pallets, load items that are of similar size and weight together while keeping the heaviest items at the base of the pallet. If the items vary in shape or size, the risk of an incident increases.

When loading pallets, evenly distribute the load and avoid packing all the heaviest items on one side of the pallet and lighter items on the other.

Load and stack items that have sharp edges or corners near the middle of the pallet so that they are protected by other items around the edges of the pallet.

Load and stack items as close to the edge of the pallet or previous layer as possible without hanging over. This helps preserve structural integrity, lowers the risk of injury, and allows straps to secure the items on the pallet.

Once the pallet is fully loaded, secure the items on it to help prevent them from shifting during transit. Use shrink wrap, plastic wrap, bands, or a combination of those methods, but make sure you’re following your company’s guidelines.

If you’re using shrink wrap to secure the pallet’s load, wrap from the bottom of the pallet up and apply consistent pressure throughout the wrap so the wrapping doesn’t come undone at the base of the pallet.

If you’re using straps to secure the pallet’s load, use ones that are made from steel, polypropylene, polyester, or rayon. Wrap the straps around the pallet and its load to make sure it’s fully secure.

Pallet Stacking Methods

-

There are various different methods you can use when stacking pallets depending on what type of items are on the pallet. This PDF-only topic will teach you about the different methods and when you should use each one.

-

PDF module (This module was created in a tool that is not supported by our Content Studio offering.)

-

This topic is currently available in English.

-

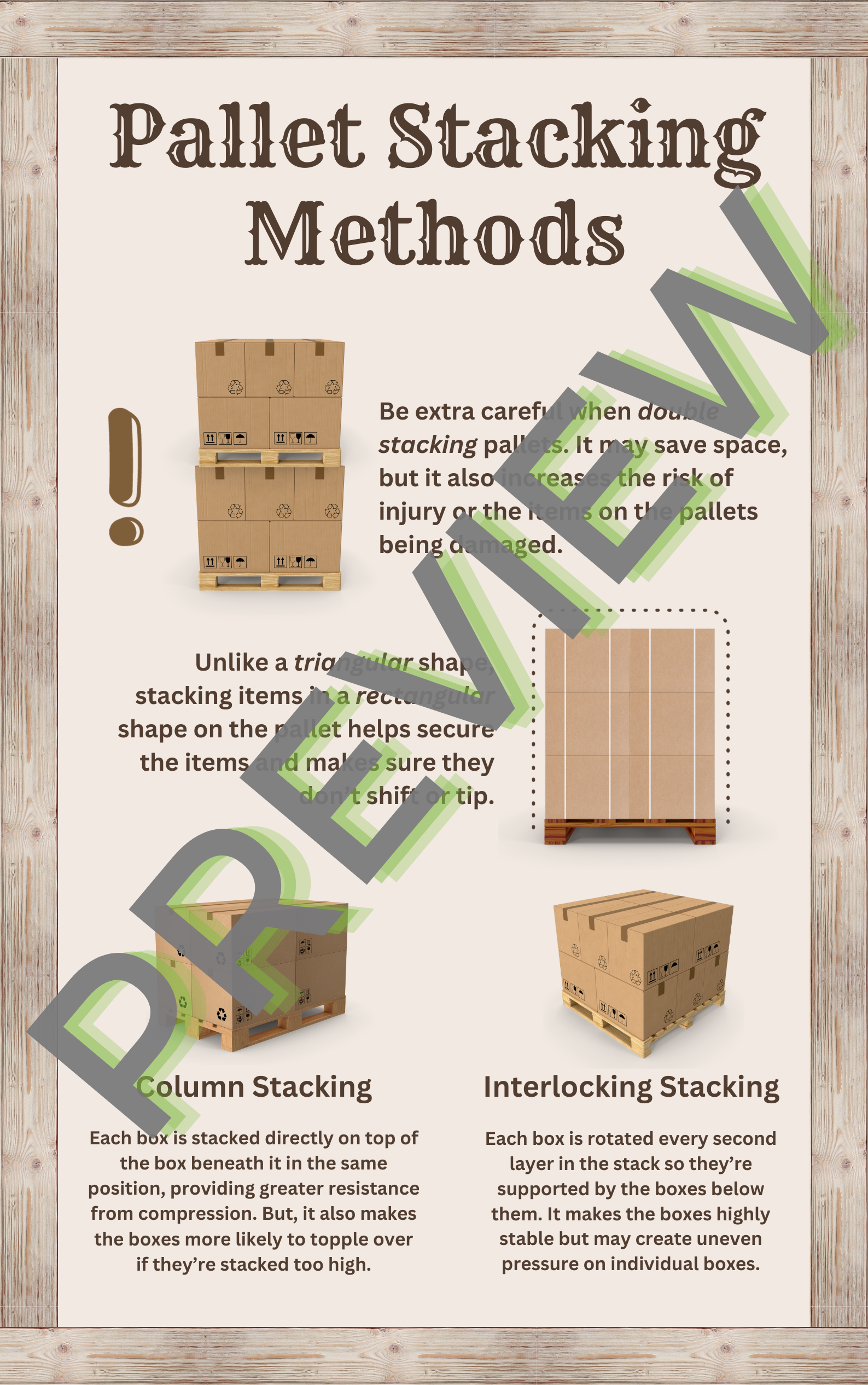

Be aware when double stacking pallets. Double stacking may help save space, but doing so can greatly increase the risk of injury or damage to the pallets and the items stacked on them.

Column stacking is when each box is stacked directly on top of the box beneath it. This provides greater resistance from compression, but also makes the boxes more likely to topple over if they’re too high or heavy.

Interlocking stacking is a method in which boxes are rotated each layer that they’re stacked so they’re supported by the ones below them. It makes the boxes highly stable but may create uneven pressure on individual boxes.

Stacking boxes in a rectangular shape provides the most structure on pallets, so avoid stacking them in a pyramid shape.